Electronics manufacturing service (EMS) companies operate both as contract manufacturers and service providers. In short, EMS companies can help you go from a technical specification, to functional prototype and final assembly – all under one roof.

In this guide, we list some of the leading Electronics manufacturing service (EMS) companies in Europe. We also explain what truly matters when you select your EMS partner.

Supplier Overview

Supplier qualifications

Industry overview

Pricing model

European EMS companies tend to have a transparent pricing model. That said, their pricing model is more complex than a single unit price. Instead, you will be charged for the provided services – which can include product development and compliance support.

You will also need to pay for the hardware cost incurred when building prototypes. Finally, the unit price is often calculated based on the material and labour cost, plus a fixed margin. However, the initial quote is normally only an estimation as the final cost depends on the material cost at the time of production.

Example

- Materials and components: 14 EUR per unit

- Labour cost: 3.5 EUR per unit

- Added margin: 1.4 EUR (8% of materials + labour cost)

Total: 14 + 3.5 + 1.4 EUR = 18.9 EUR

Product development

Electronics manufacturing service (EMS) companies generally do not have ODM products. In short, these companies tend to be purely OEM in the sense that they exclusively make products based on the customer’s design. This in turn requires that you have the electronic engineering expertise required to create a complete technical specification.

Example

- Casing design/CAD files

- PCB schematic

- Wiring diagram

- Bill of materials

- Firmware

- List of product standards

Some EMS companies provide product development support. However, most EMS companies only provide support to the extent that they improve upon your existing product specification. Approaching an EMS company in Europe with only an idea or presentation is usually not a good way if you want to be taken seriously.

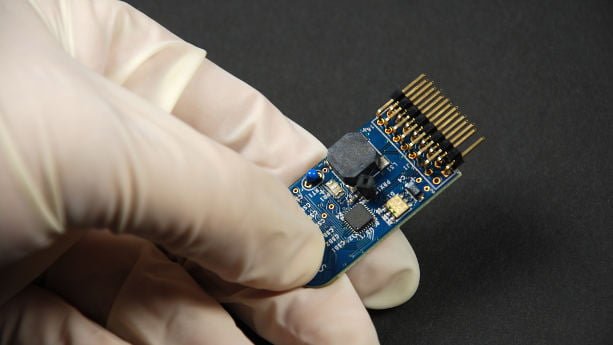

Prototyping

It is essential to have a prototype built and tested prior to entering mass production. Electronics manufacturing service (EMS) companies normally manage prototype development in-house, for a fee.

Process

1. Procure components

2. Build functional prototype

3. Approve functional prototype

Injection moulds can also be developed as part of this process, but often at the stage when the functional prototype has been approved.

Assembly

Qualified EMS companies can offer in-house assembly and mass production. As mentioned, the unit price is normally calculated based on the material cost with a predetermined margin added.

Product compliance

All electronic products manufactured for the EU market must be CE marked, which in turn requires that the product is compliant with certain harmonised standards, tested, correctly labelled, and documented. EMS companies are not compliance consultants – but should be able to help with ensuring that the product is designed to be technically compliant.

Keep in mind that electronics compliance requirements also exist in the US and UK.

| Country/market | Examples |

| EU | 1. Low Voltage Directive 2014/35/EU

2. Electromagnetic Compatibility Directive 2014/30/EU 3. RoHS Directive 2011/65/EU 4. Radio Equipment Directive 2014/53/EU 5. Ecodesign Directive 2009/125/EC |

| UK | 1. Electrical Equipment (Safety) Regulations

2. Electromagnetic Compatibility Regulations 3. Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations 4. Radio Equipment Regulations 5. Ecodesign for Energy-Related Products and Energy Information Regulations |

| USA | 1. 47 CFR Part 15 – FCC – Radio Frequency Devices

2. 10 CFR Part 430 – Energy Conservation Program for Consumer Products 3. 10 CFR Part 431 – Energy Efficiency Program for Certain Commercial and Industrial Equipment 4. 10 CFR Part 429 – Certification, Compliance and Enforcement for Consumer Products and Commercial and Industrial equipment 5. 16 CFR Part 305 – Energy Labeling Rule |

MOQ requirements

The MOQ requirement depends in part on the policy of the EMS company. However, the MOQ is also dependent on the component suppliers – which means that there often is no fixed MOQ.

Poland

ASZ Electronics Solutions

ASZ Electronics Solutions is a manufacturer that can help design and assemble electronic products, electro-mechanical devices, and cable harnesses. It offers tailor-made services regarding mechanical components, laminates, and PCBs.

Its various departments, from production to R&D, provide Asian and European companies with its services, such as IPC-A-610-E (class 3) assemblies, coatings, testing, and programming.

The company’s price depends on the project’s complexity and the time needed. It can provide a quotation within 24 hours of receiving a bill of components and PCB technical documentation. It also works with contractors around the world.

According to the company website, it has ISO 9001 certification and an ESD-protected area.

Solutions

- Through-hole technology assembly and surface-mount technology assembly

- Automatic Optical Inspection (AOI) and X-ray inspection

- Conformal coating and potting, resin protection services

- Box building: final tests and assemblies

- Wire harness assembly

- Testing and programming

- IPC-A-610-E (class 3) assembly services

Location: Wrocław, Poland

Nordes Sp. z o.o.

Nordes Sp. z o.o. specialises in providing electronic manufacturing services, and can mass produce electronics as well as products with niche designs. It manufactures products such as medical and telecommunication equipment, agricultural equipment, and aviation-related products.

Its location in a technology park allows for the company to produce, assemble, and package its products and subsequently deal with the logistics. Its services include assembly, traceability, electronics designing, and after-sales support.

According to the company’s website, it is ISO 9001 and ISO 13485 certified and operates per the IPC-A-610 standard. It also lists several certificates, such as the Forbes Sustainable Diamond certification.

Solutions

- Assembly of printed circuit boards

- Electronics encapsulation

- Traceability

- Box building assembly

- Plastic injection molding

- Electronics designing, R&D

- Engineering support

- After-sales services

Location: Wrocław, Poland

Sweden

SCANFIL

Scanfil Malmö AB was founded in 1976 in Finland to manufacture sheet metal mechanics for the electronics industry. Now, it manufactures multiple products for various electronics industries. Most of its manufacturing facilities are in Europe (in Sweden, Poland, Estonia, Finland, and Germany); with two others in the USA and China. The company manufactures electronic products such as CPR machines, UAVs, air purifiers, and parcel lockers.

According to Scanfil’s website, the company is ISO 14001-certified and complies with ISO 9001 and ISO 45001 requirements. They also have ISO 13485-certified and IATF 16949-certified facilities. It was awarded the EcoVadis Silver award.

It is a member of the United Nations Global Compact initiative and abides by 7 of the UN’s Sustainability Development Goals (SDGs).

Solutions

- Electronics manufacturing

- Mechanical assembly

- System integration

- Production outsourcing

- Product development

- Rapid prototyping

- Test development

- Distribution

- Repair and refurbish

Location: Malmö, Sweden

Denmark

GPV Group A/S

GPV Group A/S was founded in 1961 as Glostrup Plade Vaerksted. In 2000, the company implemented its electronics manufacturing services. Its manufacturing facilities use processes such as SMT, THT, coating measurement, and Package-on-package.

The company has multiple certificates, all of which are listed on its website. It has QMS certificates such as ISO 9001, IATF 16949, and NATO security certified (DK); its workmanship certificates include IPC-A-610 class II and III, IPC-A-620, and UL approval; its people and environment certificates include ISO 14001, ISO 145001, and TLS 8001.

Solutions

- Product and application design

- Test design and development

- Fast electronics prototyping

- New product introduction

- Electronics manufacturing services

- Mechanics

- Cable harness assembly

- Box-build and system integration

Location: Vejle, Denmark

France

LACROIX

Founded in 1971, LACROIX has been providing EMS for more than five decades and specialises in designing and producing electronic assemblies and sub-assemblies. The company also develops end-to-end design solutions for its clients’ electronic products.

It manufactures and provides EMS to sectors such as automotive, home and building automation, healthcare, civil avionics, and defence. It can also provide CE marking, EMC expertise, and FMEA products and MTBF calculations.

The company partners with global electronics companies, universities, as well as institutional organisations. According to LACROIX’s website, its certificates include ISO 9001, ISO 14001, EN 9100, ISO 13485, and IATF 16949. Its qualifications include UL ZPVI2/ZPVI8 approval, as well as Part 21G and Part 145 approval. It was also awarded an EcoVadis silver award.

Solutions

- Designing

- Industrialising

- Manufacturing

- Sustaining

- Project management

- Purchasing

- Logistics

- Quality assurance

Location: Beaupréau en Mauges, France